Air-to-Air Heat Exchangers

Reliable Gas Cooling for High-Temperature Processes

In industrial systems where exhaust gases can reach temperatures of 500°C or more, safe and efficient cooling is essential. At Air Fractal, we use advanced air-to-air heat exchangers to reduce gas temperatures before they reach sensitive equipment like bag filters. These systems are designed with smart control and safety features to respond quickly to sudden temperature spikes, ensuring stable operation and protecting downstream components.

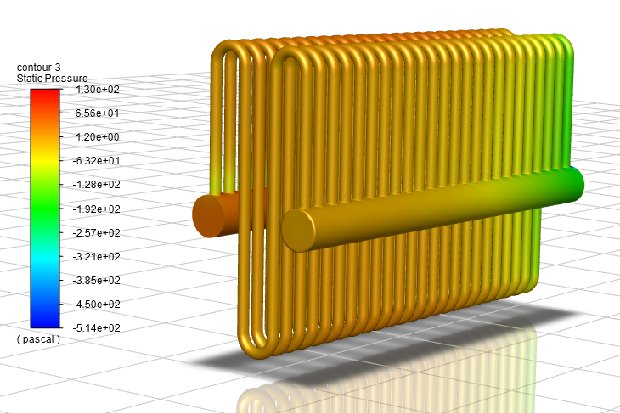

Our heat exchangers work by transferring heat from the hot exhaust gas to ambient cooling air. This is typically done using a cross-flow or cross-counterflow design, which is ideal for dry exhaust gases. The gas flows through tubes, while cooling air—driven by axial fans—passes around the tubes to remove heat efficiently.

Depending on the application, we offer single-stage or multi-stage designs, with flexibility on both the hot and cool air sides of your system. Tube sizes and configurations are tailored to meet your process needs, and we ensure consistent mechanical stability and thermal compensation throughout the unit.

For added safety and control, cooling fans can be grouped or operated individually. Emergency cooling options are also available for systems that require extra protection in extreme conditions.